子供用お箸の成形

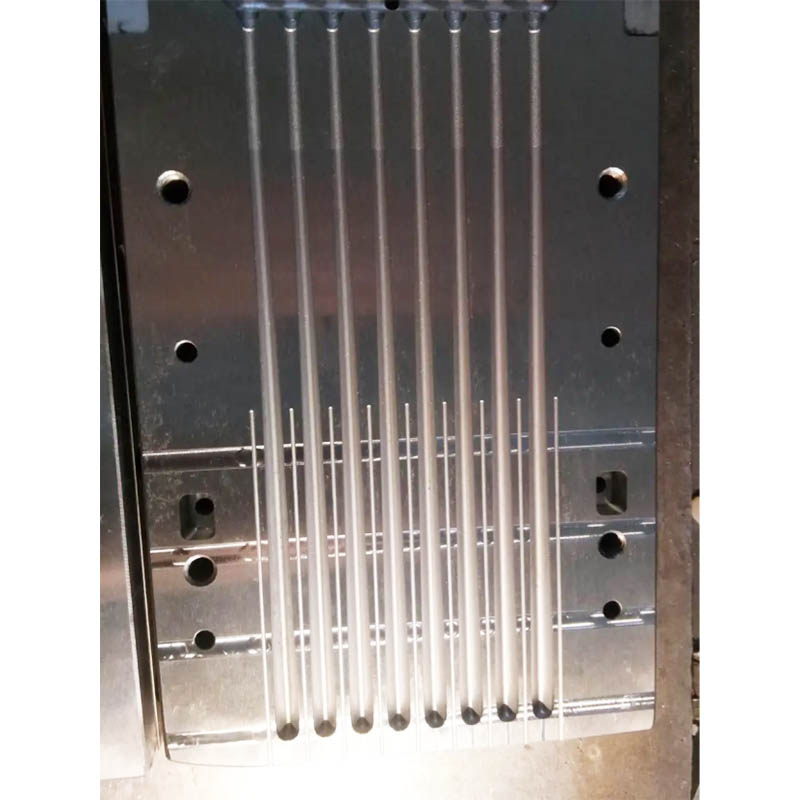

P&M カスタム子供用箸のプラスチック金型。P&M は 15 年の金型製造技術を持ち、子供用カスタム箸の成形をカスタマイズします。私たちが提供するのはプロフェッショナルなカスタム金型サービスです。射出成形、ブロー成形、ダイカスト、ロトプラスチック成形を使用できます。私たちはプラスチック金型の専門メーカーです。P&M Mold はお客様に高品質の子供用食器金型を提供することに尽力しています。当社は子供用食器の重要性を理解しているため、製品の品質を厳格に管理し、慎重な設計と製造プロセスを通じて、金型が最高の基準を満たしていることを確認します。こども型用のお箸の製造工程では、細部までこだわりを持って製造しております。箸の形状やスプーンのデザインを問わず、高精度のフライス盤を使用して金型スライダーを作成し、金型の精度と完璧な一致を保証します。当社のエンジニアチームは豊富な経験を持ち、お客様のニーズや設計要件に応じて理想的な金型を正確に製造できます。最高水準の生産能力と製品品質を確保するために、当社は数トンの金型射出成形機を保有しています。これにより、さまざまなサイズの注文に柔軟に対応し、生産プロセスの効率と一貫性を確保することができます。

お問い合わせを送信

We strictly control every production link, from the selection of raw materials to the process of mold injection molding, to ensure that every piece of children's tableware mold meets strict quality standards. In addition, P&M mold has always adhered to the concept of automatic processing. We continue to introduce advanced technology and equipment to improve production efficiency and product quality. Through automated processing, we are able to ensure the stability and consistency of the production process and reduce the influence of human factors on the product, thus providing high-precision and high-quality children's tableware molds. We are convinced that through our professional perspective and strict management, P&M molds can provide you with children's tableware molds that meet the highest standards. Whether you need a custom shape, size or design, we will be happy to provide you with excellent products and quality service. Please feel free to contact us and let us work together to achieve your needs and goals.

Chopsticks for kids mold & chopsticks for kids molding Introduction

P&M is a manufacturer specializing in the production of high-quality children's chopstick molds. We are High-volume plastic mold maker,we can custom plastic injection mold,Most of these products are made using the injection molding process.We pay attention to detail and utilize high-precision mold milling machines to create mold slides, ensuring precision and perfect fit. We offer mold injection machines of various tonnages, ensuring productivity and high standards of quality. We are known for our professionalism and cost-effectiveness. Our team of engineers has extensive experience designing reliable, durable molds. Use high-quality steel and advanced technology to ensure mold quality. Automated production lines increase efficiency and reduce the human factor. We focus on product safety and appearance design, and can customize molds according to requirements to meet the needs of different brands. Working with P&M, you will receive excellent quality and excellent service. We are committed to providing you with professional solutions. Contact us for your chopsticks for kids mold needs.

Chopsticks for kids mold & chopsticks for kids molding Parameter (Specification)

|

Mould Name |

Chopsticks for kids(mold) |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Moud precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Origin |

Made in China |

|

Runner |

Cold runner and hot runner |

|

Package |

Carton |

Chopsticks for kids(mold) Feature And Application

P&M is a well-known plastic mold maker that produces various high-precision and high-capacity plastic molds at the lowest price. It is not only a professional plastic mold manufacturer, but also an injection mold factory that provides complete solutions for the plastic molding industry. It also helps customers without production capacity to produce products. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

Plastic children's chopsticks are molded only by injection molding. Chopsticks raw materials are basically the choice of PP material, PP material is non-toxic and harmless, which is the most appropriate. Complete injection molding method: We put PP raw materials into the barrel, the injection mold into the injection molding, the engineer will adjust the machine parameters, and then officially produce plastic children's chopsticks, and there will be a mechanical arm to just complete the production of children's chopsticks from the injection molding machine inside. This results in a perfect injection molding process.

P&M has outstanding advantages in making Chopsticks for kids(mold), focusing on safety, practicality and quality. We use food-safe materials to make our molds, ensuring they are harmless and free of harmful substances. Our molds are designed with children in mind, providing optimal size, shape and comfortable hold. Safety is our top priority and we have rounded the tips of our chopsticks to prevent potential injuries. Our molds are durable, easy to clean, and maintained regularly to ensure longevity and hygiene. We focus on the smoothness and appearance of the chopstick surface, paying special attention to these details during the mold making process. Through strict quality control measures, we ensure that the molds meet design requirements and standards. We have established a comprehensive documentation system to facilitate traceability and management of the mold manufacturing process. When you choose P&M, you will get high-quality children's chopstick molds that focus on safety, practicality and quality. We provide reliable solutions for your mold needs.

As a plastic injection mold maker, compared with other suppliers, PM focuses on four aspects when making children's spoon molds: The first point is safety: children's spoons are usually made of food-grade plastic materials and are considered Relatively safe and pollution-free. Toxic and harmless. In addition, the edges of children's spoons are usually rounded and designed to be appropriately sized to avoid damaging the child's mouth. The second point is that it is suitable for children: children's spoons are usually designed with the special needs of children in mind. They often have handle designs that are easy for children to hold and operate. The third point is the interesting appearance: children's spoons usually have bright colors and interesting shapes, such as animal shapes, cartoon characters, etc. The fourth point is that it is light and easy to clean: children's spoons are usually lighter than ordinary spoons and suitable for little hands. hold. They are also relatively easy to clean and can be washed by hand or in the dishwasher.

P&M not only produce Chopsticks for kids mold, but also customize plastic products for various industries, widely used in transportation, packaging, postal and telecommunications, communication, construction, home appliances, computers and other fields. Because we have a very large factory facility to provide us with production, which is also a source of our confidence. We offer you the best price, best service, and a timely logistics choice.

P&M Chopsticks for kids mold & chopsticks for kids molding Details

When it comes to the needs of custom plastic molds, injection molds, and plastic mold manufacturers, our P&M company is your preferred partner. We focus on providing customized mold services and are committed to meeting your unique needs. P&M injection mold focuses on the following aspects in mold design to obtain excellent mold performance and production efficiency, at the same time, we provide a variety of material options for you to meet the different appearance, strength, and other requirements of the product.

Advantages of material selection: P&M pays attention to selecting the most suitable materials in mold design. With a deep understanding of expected production volumes, part requirements and cost considerations, P&M is able to select the most appropriate mold material to achieve high durability, excellent thermal conductivity and lower manufacturing costs.

Advantages of mold surface treatment: P&M focuses on selecting appropriate mold surface treatment methods. Through treatments such as polishing, electroplating or coating, P&M can improve the surface quality and wear resistance of the mold, reduce friction and wear, and extend the service life of the mold.

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Product packaging

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

Factory

Video-1: (Factory Video)

Video-2: (Injection Molding)

Video-3: (Blow molding)

Video-4: (Blow molding)

Video-5: (Roll molding)

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 15 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We are plastic iniection mold maker, we have High-quality mold manufacturing, our main feature is Custom injection mold, we focus on Plastic mold design and manufacturing. We provide Custom injection mold service.We always adhere to the principle of quality first and time first. While providing customers with the best quality products, we try to improve production efficiency and shorten production time. We are proud to tell every customer that our company has not lost a single customer since its inception. If there is a problem with the product, we will actively seek solutions and take responsibility to the end. Please choose us and let us become a long-term cooperation partner.

FAQ

1. Who are we?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern.

Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment.

3. What can you buy from us?

Mould,Plastic Product,Metal Product,Dental Product,CNC machining.

4. Why should you buy from us not from other suppliers?

Ningbo P&M Plastic Metal Product Co., Ltd. We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply:3d design - 3d printing - mold making - plastic injection

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FCA,DDP,DDU;

Accepted Payment Currency: USD,EUR;

Accepted Payment Type: T/T,L/C,PayPal,Western Union,Escrow;

Language Spoken: English,Chinese,Spanish,French,Russian.

6. What are the characteristics of your service?

1. Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.