ヨガツールの成形

これは中国のP&Mです。P&Mはプラスチック射出成形金型のサプライヤーです。カスタムヨガツール成形サービスを提供したいと考えています。私たちの工場は15年以上操業しています。私たちが提供するのはプロのカスタム金型サービスであり、プロのヨガツール成形です。射出成形、ブロー成形、ダイカスト成形、ロトプラスチック成形が可能です。 ヨガツール製品には、ヨガブロック、ゴムバンド、スタッフ、ゴムバンド、ヨガウォールロープなどがあります。ホイールヨガ、フローヨガ、エアリアルヨガ、ヨガボール、ウエストストレッチャーなどです。これらの製品の特性上、原材料は柔らかいことが求められます。そして耐久性があります。

お問い合わせを送信

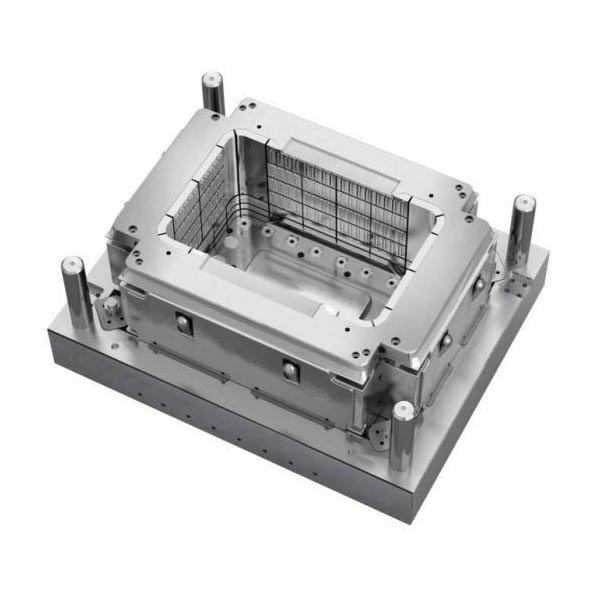

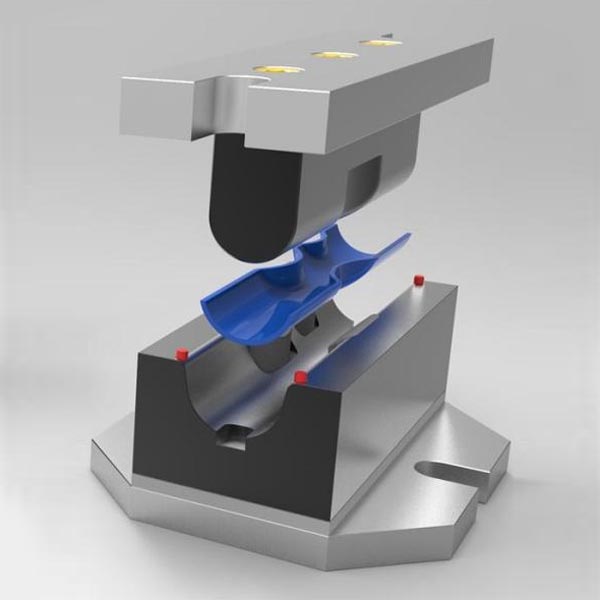

These products are mainly produced through two mold processes: injection molding and hot press molding. We are Plastic mold maker, we can provide Professional custom yoga tool molding service, These two molding methods, we can make. If the injection molding process is used, there are two types. One is a hard product like a waist lifter. The main material is PP material. The material will be very durable and have a certain degree of softness.

The other is products like yoga bricks or elastic bands, which require high softness. The raw materials can be plastic raw materials such as TPU or TPE, which are also very durable. Advantages and disadvantages of this molding method: 1. Advantages: The unit price of the product is cheap and the production time is fast. 2. Disadvantages: high mold cost and complex structure.

If the hot pressing molding process is used, similar to products such as yoga bricks or elastic bands, the raw materials are required to be rubber or silicone materials, and the mold can be directly hot-pressed using aluminum plates. The advantages and disadvantages of this method: Advantages: The mold cost is low, The production time is fast and the structure is simple. Disadvantages: The unit price of the product is expensive (because the raw materials of rubber and silicone are expensive), the processing time is long, and manual and semi-automatic assistance is required for production.

There is another EVA foam mold. We also have experience. This process is in the aluminum mold by adding polyurethane foam raw materials, on the hydraulic press molding. The polyurethane foam produced this time has corrosion resistance, wear resistance and high temperature resistance. There are many yoga bricks that are also made using this process. The advantages of this molding process: low mold cost, mold materials can choose plastic, steel and aluminum, which can be determined according to the customer's own requirements. Disadvantages: The product material can only choose polyurethane, the raw material is single, the labor cost is high, the production needs manual assistance, and the production time is slow.

As long as you want to customize accessories or parts for similar yoga tool molds, please contact us, we have enough technology and experience to help you complete this project. We can provide one-stop service. Design - mold making - product production - transportation, we are a complete production chain. Our factory can meet your requirements. Please contact us

Yoga tool Mould & Yoga tool molding Parameter (Specification)

|

Mould Name |

Chopsticks for kids(mold) |

|

Mould Time |

20-35 Days |

|

Product time |

7-15 Days |

|

Moud precision |

+/-0.01mm |

|

Mould life |

50-100 million shots |

|

Producing Process |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

Mould cavity |

One cavity, multi-cavity or same different products be made together |

|

Mould material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Runner system |

Hot runner and cold runner |

|

Base material |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

Finish |

Pitting the word, mirror finish, matte surface, striae |

|

Standard |

HASCO, DME or dependent upon |

|

Main thechnology |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

Software |

CAD,PRO-E,UG Design Time: 1-3 days (normal circumstances) |

|

Product material |

ABS,PP,PC,PA6,PA66,TPU,POM,PBT,PVC,HIPS,PMMA,TPE,PC/ABS, TPV, TPO,T PR,EVA,HDPE,LDPE,CPVC,PVDF,PPSU.PPS. |

|

Origin |

Made in China |

|

Runner |

Cold runner and hot runner |

|

Package |

Carton |

Yoga tool Mould & Yoga tool molding Feature And Application

P&M As a professional yoga tool molding manufacturer, we can meet all the points of Yoga tools production. We pay attention to the selection of materials and use high quality metal materials to ensure the strength and durability of Yoga tools, while meeting the relevant safety and quality standards. We have a professional design team that can provide the right Yoga tools design and size according to the needs of customers and market trends. We pay attention to ergonomics and comfort, ensuring that the grip part of the Yoga tools fits the shape and size of the human hand, so that the user feels comfortable. P&M has advanced mold manufacturing technology, we manufacture high-precision molds to ensure the accuracy of the shape and size of the Yoga tools. Our molds are durable and reliable to meet long-term production needs. In the process of processing and manufacturing, we use advanced equipment and processes to accurately cut, shape and weld metal materials to produce high-quality Yoga tools main structure. Quality is our primary concern and we exercise strict quality control in the manufacturing process. Each Yoga tools is dimensional checked, strength tested and visually inspected to ensure that it meets quality standards. We can also carry out personalized identification for Yoga toolss, including product information and brand identity, etc., and take appropriate packaging to protect the Yoga tool molds during transportation and storage. We will provide customized Yoga tools fabrication solutions according to your requirements and specifications to ensure that your needs are met. Whether it is quality control, or the details of design and manufacturing, P&M will go all out to meet your requirements and provide you with high-quality Yoga tools products.

In addition, P&M has the ability to customize indoor sports programs. In addition to Yoga too Mould, we can also help design and manufacture molds and plastic products for other indoor sports equipment. Whether it is the mold of customized sports equipment or the corresponding plastic parts, we are able to provide professional solutions according to the requirements of customers. We are committed to providing our customers with a diverse selection of products, ensuring they have high quality indoor sports equipment that promotes a healthy and active lifestyle. P&M has a complete development and production system, capable of mold design, plastic product manufacturing and automated production. We are guided by the needs of our customers and provide them with customized solutions. Our goal is to provide customers with quality products and satisfactory service, and establish long-term cooperative relations with them. Whether you are looking for custom Yoga tool molds or molds and plastic products for other indoor sports equipment, P&M can meet your needs. Contact us and let us work together to create exceptional custom products that add quality and value to your indoor sports program.We believe that by cooperating with P&M, you will obtain Yoga tool molds that meet high standards and provide excellent performance and quality for your production.

P&M Custom Yoga tools molding & Yoga tool molding Details

When it comes to the needs of custom plastic molds, injection molds, and plastic mold manufacturers, our P&M company is your preferred partner. We focus on providing customized mold services and are committed to meeting your unique needs. P&M injection mold focuses on the following aspects in mold design to obtain excellent mold performance and production efficiency, at the same time, we provide a variety of material options for you to meet the different appearance, strength, and other requirements of the product.

Advantages of material selection: As a Professional custom yoga tool molds maker, P&M focuses on Plastic mold design and manufacturing. Regarding mold materials, we will use your in-depth understanding of the product's life, expected output, parts requirements and cost considerations. , thus selecting mold materials such as No. 45 steel/P20/718/718H/S136/H13. P&M can optimize your project by selecting the most appropriate mold materials for high durability, excellent thermal conductivity and lower manufacturing costs.

P&M has High-quality mold manufacturing, and our advantages in mold surface treatment: P&M focuses on choosing the appropriate mold surface treatment method. P&M can improve the surface quality and wear resistance of the mold, reduce friction and wear, and extend the service life of the mold through mold polishing, mold electroplating or coating, EDM, quenching and other treatments.

As High-volume plastic mold maker, our advantage in mold maintenance: P&M focuses on regular mold maintenance and upkeep. P&M ensures the performance and life of the mold and reduces failures and downtime in production through maintenance measures such as cleaning the mold, lubricating parts, and timely replacement of worn parts. We will perform anti-rust treatment on the surface of the mold to protect the life of the mold.

Packaging and transportation

Packaging according to your needs

1.By air ,it takes 3-7 days for delivery .The goods can be shipped by DHL ,Fedex ,UPS .

2.By sea ,the delivery time is based on your port .

To South East Asian Countries takes about 5-12 days

To Middle east countries takes about 18-25 days

To European countries takes about 20-28 days

To American countries takes about 28-35 days

To Australia takes about 10-15 days

To African countries takes about 30-35 days.

As a yoga tool mold manufacturer, we focus on quality and efficiency. We use advanced production equipment and processes to ensure the accuracy and durability of our molds. We also focus on delivery time and strive to complete mold manufacturing and deliver to customers within the stipulated time. When you choose our P&M company, you will receive first-class custom plastic mold services. Our goal is to provide you with quality products and professional customer service. No matter the size of your project, we work hard to ensure your satisfaction. Contact us and let us be your reliable partner to achieve your plastic mold manufacturing goals!

Mold design:

Information you need to provide us

1. If you have drawings, 2D drawings, 3D drawings (preferably in STEP format).

2. If there are no drawings, you need to provide specific length, width, height and weight information. (It’s best to send us samples)

3. Should the mold be sent to your country, or leave the mold in our factory and we will help you produce the product.

4. Mold material requirements, cavity number requirements (you can tell us about the size of your injection molding machine)

5. Product material requirements and product quantity. (You can tell us about the use of the product and we can give you suggestions)

Factory

We are Custom Plastic Mold factory. Our factory is plastic injection mold maker. we has 15 years of experience in professional custom plastic mold and 10 years of foreign trade experience. We are custom Plastic Mold supplier. We can provide custom Plastic Mold service. Our factory can make the Injection molded plastic parts, and the quality of the products will satisfy you.

We have more than 50 high-end machines and hundreds of engineers and designers. We can provide one-stop service, from product design - mold making - product production - product packaging - transportation. We have a complete production chain. We can meet all your requirements.

Services we provide:

Professional custom mold service, Plastic mold design and manufacturing .plastic product production, product design, mold design, blow mold customization, rotational mold customization, die-casting mold customization. 3D printing services, CNC manufacturing services, product packaging, customized packaging, shipping services.

We are plastic iniection mold maker, we have High-quality mold manufacturing, our main feature is Custom injection mold, we focus on Plastic mold design and manufacturing. We provide Custom injection mold service.We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment. If there is a problem with the product, we will seek a solution actively and take responsibility to the end. Please choose us and let us be partners in long-term cooperation.

P&M adheres to being market-oriented, taking quality as its life, focusing on high-quality services and constantly developing new products, determined to establish a better corporate image, and conduct extensive business exchanges and cooperation with friends at home and abroad to create brilliance together.

Quality control

There is a mighty professional team in the quality department. They who whole strong technical ability and great responsibility spirit take charge quality control and checkout of the whole course of mold manufacture and final mold qualification. Equipped with in-house mold trial injection machines with state-of-the-art measuring equipment . Build up firm "quality is first, all satisfy customers" idea. It has each 3D measurement, 2D measurement, color meter measurement etc instrument to aid quality control.

FAQ

1. Are you a trading company or a manufacturer?

We are a manufacturer as you can see our workshop as above.

2. What is your terms of payment?

50% Mold cost deposit,balance mold cost +50% production cost paid when samples confimed,Balance production cost paid against copy of B/L. We accept T/T

3. Do you support OEM ?

Yes, we can produce by technical drawings or samples.

4. How about your delivery time?

Generally, it take 40 days ( 30 days do mold and 10 days do mass production).

5.Why Choose Us?

– We’re up to date with the latest techniques, combine innovation thinking with exact plastic molding knowledge, ensure your molds get off to the best possible start.

– Under unique mold design, strict management and quality control, we promise the best molds offer to you.

Durable mould with long life and easy maintenance, greatly save your time! Time is money! We just focus on it and try best to return your invest back and get benefits.

Develop on quality, win win on honesty is what we strongly insist!

Anyway, if you’re still looking for the good dustbin mould maker in China, we can be your another good choice. Welcome your new inquiry!

6.What is your MOQ?

There is no MOQ requirement for customized products, just tell us your first batch quantity and annual demand, we will choose the most suitable mold material and cavity for you, save your cost to the greatest extent and let our quotation have an advantage

7.How long it takes you to provide the designing options for us?

This depends on the situation. We need to know the specific needs of customers, and we can make drawings. The drawing production time is about 3-4 days.

8 .What are the characteristics of your service?

1. Your message will be replied within 1 hour (except sleep time) Your inquiry related to our products or prices will be replied within 24hours.

2. Welltrained and experienced staffs to answer all your enquiries in fluent English.

3. Offering the support to solve the problem in the application or selling period.

4. Competitive prices based on same quality.

5. Guarantee samples quality same as mass production quality.