Stack Mold Technology

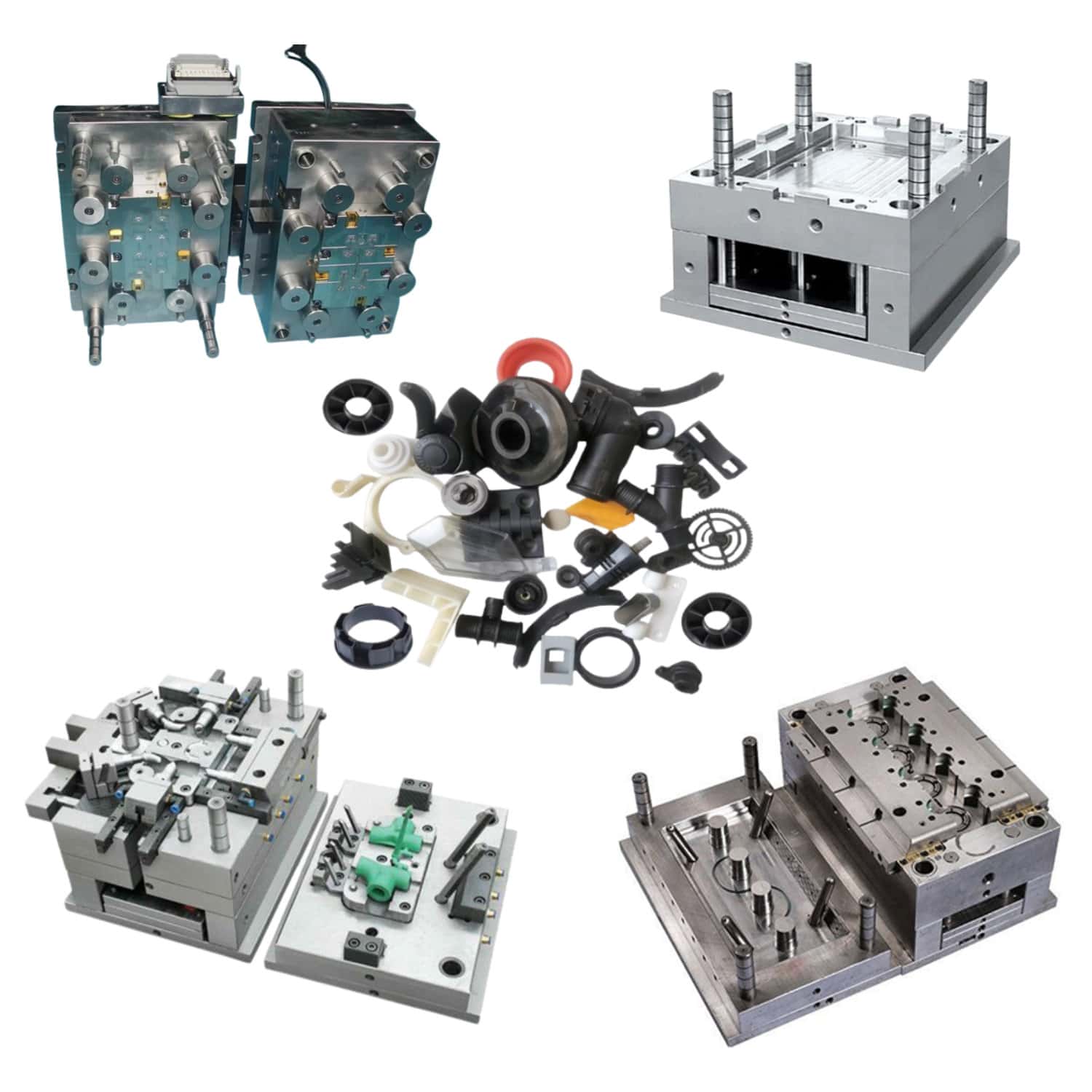

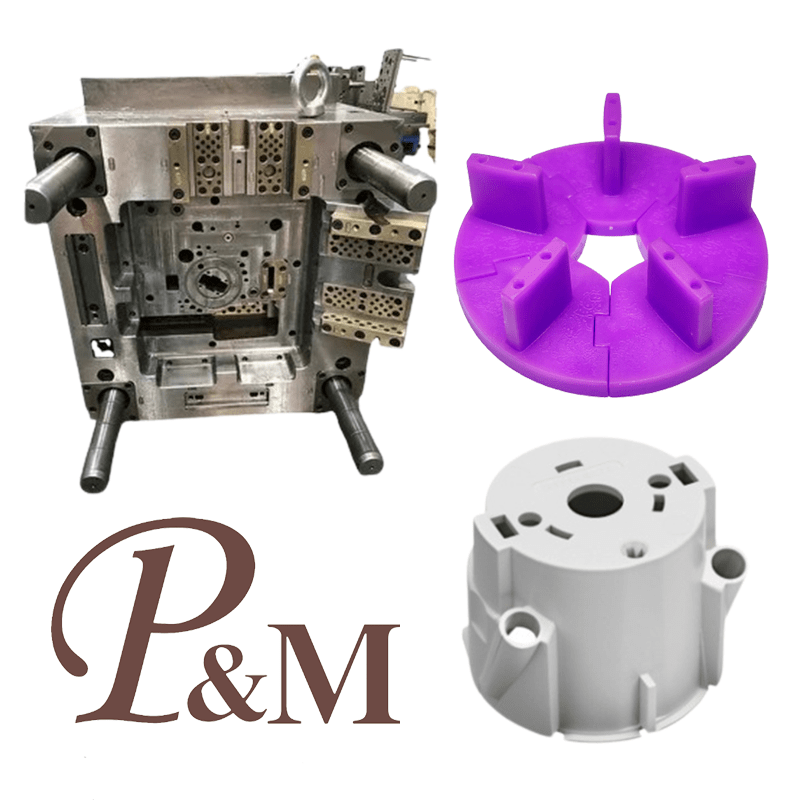

寧波 (P&M) は、プラスチック製品のカスタマイズされた金型の 15 年の金型製造技術を持っています。当社は ISO 9001 認証を取得しています。私たちはプロのカスタム金型サービスを提供し、プロのプラスチック金型メーカーです。製品の原材料選定や金型材料の選定など、豊富な経験を持っております。私たちはさまざまな材料の特性と金型設計の長所と短所を熟知しています。お客様に最適な素材と専門的なデザインアドバイスをご提案させていただきます。

お問い合わせを送信

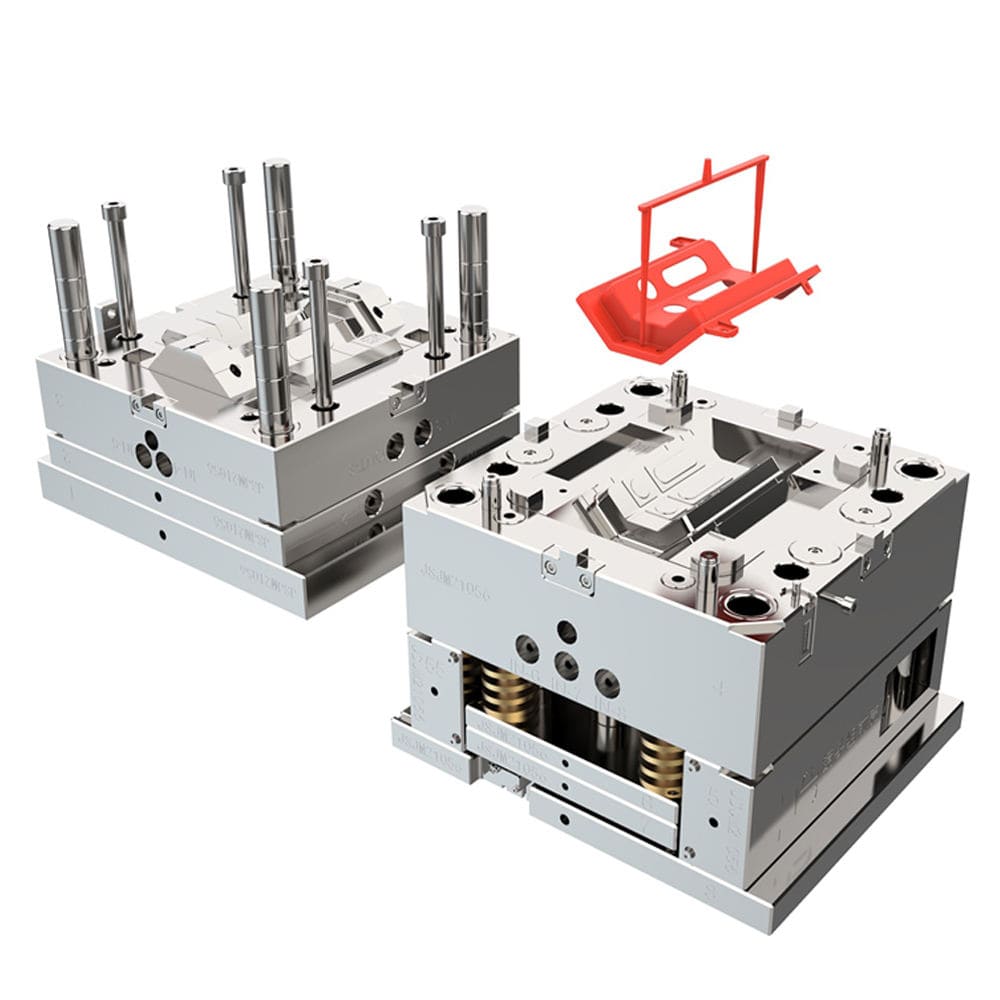

We offer solutions utilizing Stack Mold Technology for extremely high-volume, multi-layer, or multi-component parts. Our advantage is Volume Doubling, effectively doubling the output from a single machine cycle. Tooling Design involves complex runner plates and precision alignment systems. Advanced Technology ensures flow balance across both parting lines. Our Stack Mold Technology delivers unmatched high efficiency and cost-effectiveness.

P&M 射出成形用ラピッドツーリングの概要

1、コア機能: カスタマイズされたニーズに適応するプロフェッショナルの利点

The characteristics of customized professional plastic injection molding are closely centered around customer personalized needs and high-quality production goals, mainly reflected in the following five dimensions:

1. 高度にカスタマイズ: パーソナライズされたニーズを正確にマッチング

2. 強い材料適応力:あらゆるプラスチックの需要をカバー

3. 高精度・高安定性:安定した製品品質を確保

4. 効率的な生産とコストの最適化: 品質と効率のバランス

5. フルプロセスのプロフェッショナルサービス: 製品ライフサイクルをカバー

2、 Production process: professional operation of the entire chain from demand to finished product

The production process of customized professional plastic injection molding is a complex system engineering that integrates design, manufacturing, testing, and service. Each link requires professional technology and strict control, usually including the following 9 core links:

1. 要件の伝達とスキームの計画

This is the starting point of customized production and the key to ensuring the smooth progress of subsequent processes. Firstly, the professional team conducts in-depth communication with the customer to comprehensively understand their product requirements, including product usage, performance requirements, dimensional accuracy and appearance standards, production batch and delivery cycle, cost budget, etc; Then, based on one's own technical capabilities and production experience, analyze and evaluate the requirements, determine the injectability of the product, and identify possible technical difficulties; Finally, a preliminary solution is formulated, including material selection suggestions, mold design ideas, process framework, cost estimation, and production plan. After reaching consensus with the customer, the project is officially launched.

2. 製品設計とDFM分析

After the DFM analysis is completed, the optimized product design scheme will be fed back to the customer for confirmation before entering the mold design stage.

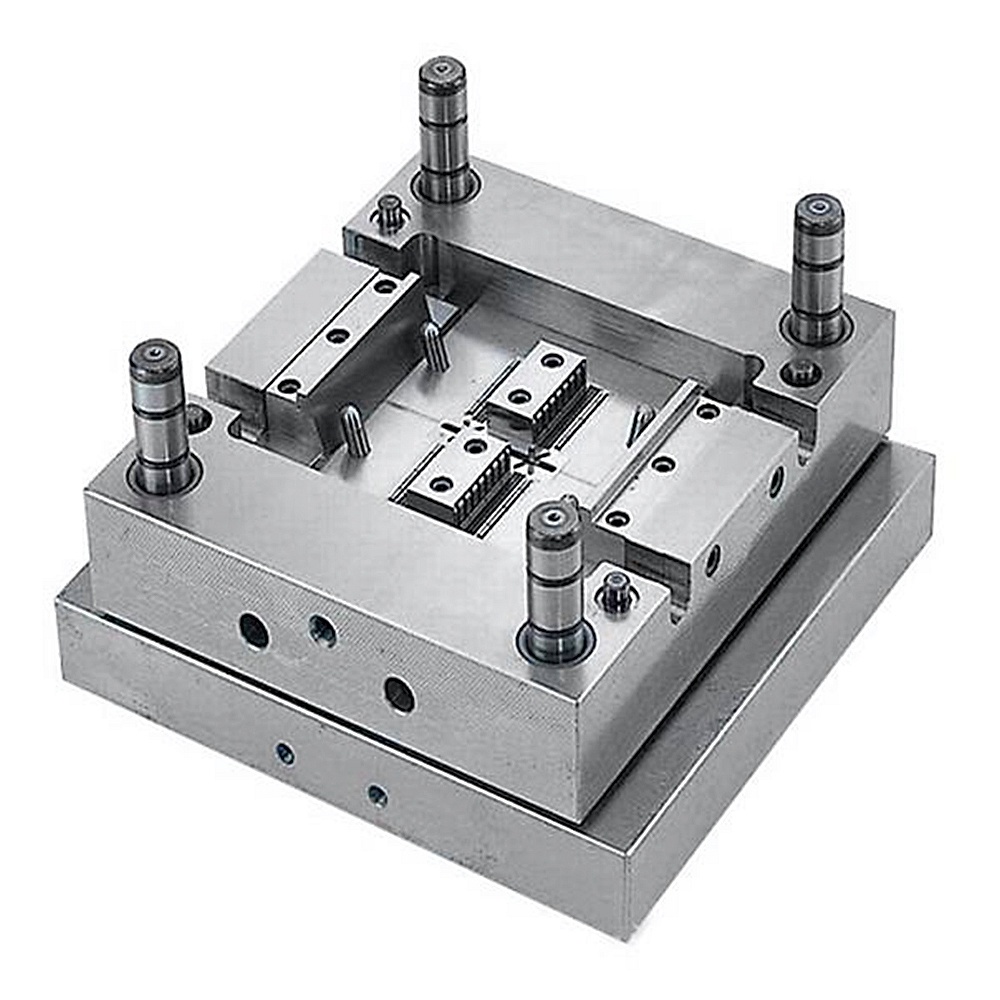

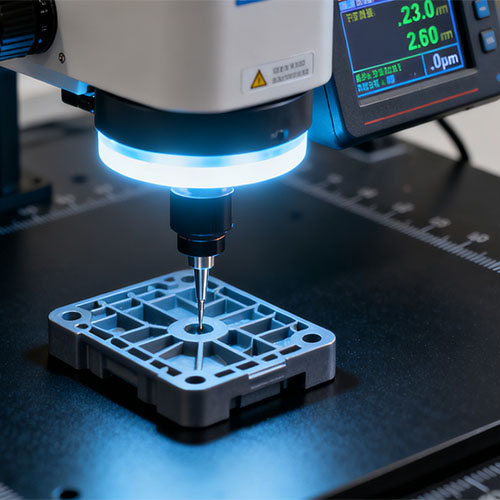

3. 金型設計・製作

Mold is the core equipment for customized professional plastic injection molding, and its design and manufacturing quality directly determine the quality and production efficiency of the product.

4. 材料の準備と前処理

Procurement and pre-treatment of plastic raw materials determined based on mold design and process plan. Firstly, conduct quality inspection on the purchased plastic raw materials, including appearance inspection and performance testing, to ensure that the raw materials meet production requirements; For plastics with strong moisture absorption properties (such as PA, PC, PBT, etc.), drying treatment should be carried out before injection molding. Moisture in the raw materials should be removed by a dehumidification dryer to avoid defects such as bubbles and silver lines during the injection molding process; For raw materials that require the addition of color masterbatch or additives, they should be uniformly mixed after drying to ensure consistency in color and performance. The mixing process is usually carried out in a high-speed mixer or screw mixer, and the mixing time and speed should be controlled to avoid overheating or uneven mixing of the raw materials.

5. 射出成形プロセスのパラメータ設定と金型テスト

Trial molding is a key step in verifying the performance of the mold and the rationality of the process plan.

6. バッチ生産とプロセス制御

試作金型が合格した後、量産段階に入ります。

7. 製品の後処理

Some plastic products require post-treatment after injection molding to enhance their performance, appearance, or meet assembly requirements. Common post-processing techniques include:

Remove trimming and trimming, surface treatment, assembly and assembly, heat treatment and aging treatment.

P&M 射出成形用ラピッドツーリング(仕様)

|

金型名 |

射出成形用のラピッドツーリング |

|

私たちは約束します |

All customer-centric, never for short-term profit, and sell long-term benefits |

|

私たちが生産します |

Mold, prototype, injection molding, product assembly, surface printing, spraying the surface integration |

|

提供してください |

2D、3D、サンプル、またはマルチアングル写真のサイズ |

|

成形時間 |

約25営業日 |

|

製品時間 |

7~15日 |

|

ファッションの精度 |

±0.1mm |

|

金型の寿命 |

5,000~1億ショット |

|

製造工程 |

Audit drawings - mold flow analysis - design validation - Custom Materials - mold processing - core processing - electrode machining - Runner system processing - parts processing and procurement - machining acceptance - cavity surface treatment process - complex mode Die - The entire mold surface coating - Mounting plate - mold sample - sample test - sending samples |

|

金型キャビティ |

1 つのキャビティ、複数のキャビティ、または同じ異なる製品を一緒に製造することができます |

|

金型材質 |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

ランナーシステム |

ホットランナーとコールドランナー |

|

基材 |

P20,2738,2344,718,S136,8407,NAK80,SKD61,H13 |

|

仕上げる |

孔食、鏡面仕上げ、マット面、脈理 |

|

標準 |

HASCO、DME、または依存 |

|

スレンダーテクノロジー |

Milling, grinding, CNC, EDM, wire cutting, carving, EDM, lathes, surface Finish, etc. |

|

ソフトウェア |

CAD、PRO-E、UG 設計時間: 1 ~ 3 日 (通常の状況) |

|

製品材質 |

食品グレードのプラスチック原料 |

|

起源 |

中国製 |

カスタマイズプロセス

工場&会社概要

NingBo Plastic Metal Product Co.,Ltd (P&M) is located in Yuyao, the so-called Mould City, Plastic Kingdom, in the southern tip of Hangzhou Bay Bridge,north of Shanghai, the east of Ningbo Port,tight double line of State Road 329 on land, sea and air trafic into a network to facilitate transport.

By the abundant technical strength,scientific management methods and good after-sales service, product deeply trusted and welcomed by customers from all over the world. P&M holds improved system of development and production, to achieve mold design, plastic products manufacturing and automatic production. Our main products is design and manufacturing of plastic mold, plastic product, metal product. 90% products of our enterprise are exported to America, Europe, Germany, Japan, Australia, etc. For many years, the company has been committed to the research of raw materials. The company has its own trademark and dozens of patents, providing more convenient technical support for mold making and product production. P&M started domestic business from 2008,named Shundi Mould Factory. And opened the international market from 2014. We always adhere to the principles of quality first and time first. While providing customers with the highest quality products, try to maximize the production efficiency and shorten production time. We are proud to tell every customer that our company has not lost any customer since its establishment.If there is a problem with the product, we will seek a solution actively and take responsibility to the end.

P&M adheres to market-oriented to the quanlity of life and focus on quality service and continuous development of new products,determined to establish a better corporate image,and our friends at home and abroad to carry a wide range of business exchanges and cooperation, create brilliant.

パッキング

ニーズに応じた梱包

1.航空便では、配達までに3〜7日かかります。

商品はDHL、Fedex、UPSで発送できます。

2.海によって、配達時間はあなたの港に基づいています。

東南アジア諸国へは約5〜12日かかります。

中東諸国へは約18〜25日かかります。

ヨーロッパ諸国へは約20〜28日かかります。

アメリカの国へは約28〜35日かかります。

オーストラリアまでは10~15日程度かかります。

アフリカ諸国へは約30〜35日かかります。

P&M Bike parts, centered around children, balances safety, health, and fun, aiming to add a bright color to children's beautiful childhood. We look forward to working together with you to serve our children.

子供の成長の道はレンガとタイルで舗装されています。

よくある質問

1.私たちは誰ですか?

We are based in Zhejiang, China, start from 2014,sell to North America(30.00%),Southern Europe(10.00%),Northern Europe(10.00%),Central America(10.00%),Western Europe(10.00%),Mid East(10.00%),Eastern Europe(10.00%),South America(10.00%). There are total about 51-100 people in our office.

2.品質を保証するにはどうすればよいですか?

大量生産の前には必ず試作サンプルを作成します。

出荷前に必ず最終検査を行ってください。

3.私たちから何を買うことができますか?

金型、プラスチック製品、金属製品、歯科製品、CNC加工。

4.他のサプライヤーからではなく、当社から購入する必要があるのはなぜですか?

We main do all kinds of 3d design, 3d printing and plastic metal molds tooling and products. We have our own engineer and factory. One-stop supply: 3d design - 3d printing - mold making - plastic injection.

5.どのようなサービスを提供できますか?

受け入れられた配送条件: FOB、CFR、CIF、EXW、FCA、DDP、DDU;

受け入れられる支払い通貨: 米ドル、ユーロ。

受け入れられた支払いタイプ: T/T、L/C、PayPal、ウェスタンユニオン、エスクロー;

話される言語: 英語、中国語、スペイン語、フランス語、ロシア語。

6.サービスの特徴は何ですか?

1. 製品や価格に関するお問い合わせは、24 時間以内に回答させていただきます。

2. よく訓練された経験豊富なスタッフが流暢な英語ですべてのお問い合わせにお答えします。

3. 申込時または販売期間中の問題解決のためのサポートの提供。

4. 同じ品質に基づいた競争力のある価格。

5. 量産品質と同じサンプル品質を保証します。